Description

LH Dealer & Supplier Near Me in Himachal Pradesh:

High-Performance Ferritic-Austenitic Welding Electrodes

Introduction: If you’re searching for a reliable welding electrode supplier near you in Himachal Pradesh, look no further. LH welding electrodes are specifically designed for high-strength applications that demand crack resistance, superior corrosion resistance, and excellent performance under friction and impact. Our ferritic-austenitic welding electrodes, formulated with a unique combination of materials, ensure smooth, defect-free welds with exceptional durability in harsh environments.

Alloy Basis:

- Iron (Fe)

- Chromium (Cr)

- Nickel (Ni)

- Manganese (Mn)

Properties: Our ferritic-austenitic welding electrodes are engineered for ease of use, producing a soft arc and smooth, defect-free welds with approximately 30% ferrite content. These electrodes provide the following benefits:

- High Strength and Crack Resistance: Ensuring welds are strong and resistant to cracking under stress.

- Superior Resistance: Effective against friction, corrosion, work-hardening, and shock.

Technical Data:

- Ultimate Tensile Strength (UTS): 70-85 kgf/mm²

- Elongation: 22-24%

This combination of strength and ductility makes LH electrodes perfect for heavy-duty applications, ensuring that your welds maintain their integrity under challenging conditions.

Typical Applications: Our high-performance ferritic-austenitic electrodes are suitable for a wide range of applications, including:

- Heavy Machinery and Equipment Parts: Ideal for parts exposed to heavy wear, like earth-moving equipment, automobile springs, and trunnions of cement mills.

- High Temperature and Impact Applications: Excellent for parts subjected to heat, corrosion, and impact.

- Joining High and Low Alloy Steels: Perfect for high carbon steels, low and high alloy steels, tool steels, spring steels, manganese steels, and more.

- Dissimilar Steel Welding: Ideal for joining dissimilar steels, ensuring a reliable and durable bond.

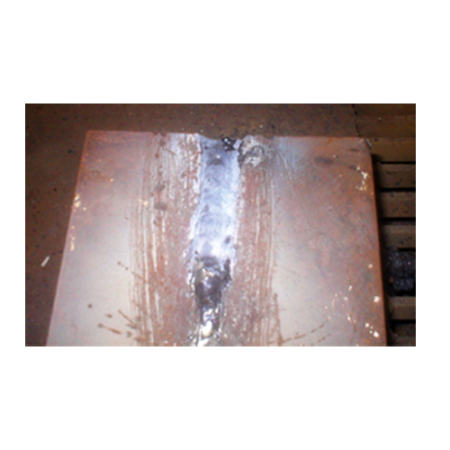

- Surfacing Applications: Used for surfacing grooved rolls and repairing drop-forge dies.

Procedure for Optimal Results:

To achieve the best welding results with LH electrodes:

- Clean the weld area thoroughly before starting.

- Prepare joint edges properly to ensure a smooth weld.

- For high carbon and high alloy steels, preheat to 200-250°C to prevent cracking, followed by slow cooling after welding.

- Use a short arc and a stringer bead technique for enhanced control.

- Hot peening is recommended for additional strength.

Welding Current Specifications:

- Current Type: AC / DC (+)

- Electrode Size (∅ mm) / Length:

- 1.6×250 mm

- 2.5×350 mm

- 3.2×350 mm

- 4.0×350 mm

- 5.0×350 mm

- Recommended Current (amps):

- 1.6 mm: 25-35 amps

- 2.5 mm: 40-75 amps

- 3.2 mm: 70-110 amps

- 4.0 mm: 90-140 amps

- 5.0 mm: 130-180 amps

Why Choose LH Electrodes in Himachal Pradesh?

As an authorized LH dealer and supplier near you in Himachal Pradesh, we are committed to delivering the highest quality welding electrodes tailored to meet the unique requirements of industries like construction, automotive, mining, and manufacturing. Whether you’re working on heavy machinery repairs, joining complex steels, or surfacing critical parts, LH welding electrodes offer the durability and performance needed for long-lasting results.

For more information or to place an order, contact us today for all your welding needs!

Reviews

There are no reviews yet.