Description

LH Dealer & Supplier of High-Quality Abrasion-Resistant Electrodes Near Me in Chandigarh

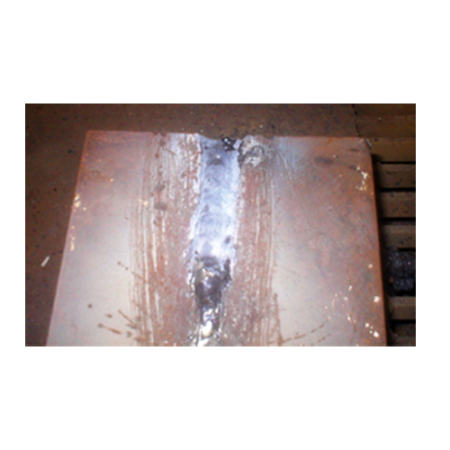

When it comes to high-performance hardfacing solutions, LH is a reliable dealer and supplier of premium-quality abrasion-resistant electrodes in Chandigarh. These electrodes are specifically designed with an alloy basis of Ni, Cr, C, and Mn, ensuring exceptional durability and performance across a wide range of industrial applications. With their ability to deliver hard, glossy, and abrasion-resistant deposits, these electrodes are the ideal choice for industries that require robust and dependable welding solutions.

Properties of LH Abrasion-Resistant Electrodes

LH’s abrasion-resistant electrodes offer outstanding performance, ensuring longevity and efficiency even in the most demanding conditions. Here’s a breakdown of their key properties:

- Highly Abrasion-Resistant: The deposits produced by these electrodes are highly resistant to wear and tear, even in the harshest environments. This resistance makes them ideal for applications that experience continuous abrasion.

- Glossy and Shining Deposits: In addition to durability, these electrodes provide smooth, glossy finishes, enhancing both the aesthetics and functionality of welded surfaces.

Technical Data

- Hardness: 58-62 RC (Rockwell C), ensuring excellent wear resistance and long-lasting protection against abrasion.

Typical Applications

LH’s abrasion-resistant electrodes are highly versatile and are widely used in the wear-resistant surfacing of mild and low alloy steels. They are perfect for industries that require materials capable of withstanding heavy abrasion and wear. Some common applications include:

- Building up machine parts

- Digger teeth

- Bucket edges

- Conveyor screws

- Mixer wings

- Oil expeller worms

- Scraper blades

- Cement die rings

- Muller tyres

- Plough shears

- Mining applications

These electrodes prove essential in industries such as agriculture, mining, construction, and more, where equipment faces heavy abrasion and extreme wear.

Welding Procedure

To achieve the best results, follow these simple but effective steps:

- Clean the Affected Area: Start by using a wire brush to remove any dirt, grease, or debris from the welding surface. This step is essential to ensure proper adhesion of the weld.

- Hold a Short Arc: Keep the arc short and position the electrode at a 90° angle to minimize dilution, ensuring a strong bond between the layers.

- Apply Multiple Layers: A maximum of two layers is recommended to achieve optimal hardness and wear resistance.

Welding Current Settings

For efficient and effective welding, the following current settings are recommended based on the size of the electrode:

- Size 3.2mm x 350mm: Current range 90-110 amps

- Size 4.0mm x 350mm: Current range 110-140 amps

- Size 5.0mm x 350mm: Current range 140-180 amps

These electrodes are suitable for both AC and DC (+) currents, offering flexibility depending on the welding equipment used.

Why Choose LH in Chandigarh?

There are several reasons why LH is the trusted choice for abrasion-resistant electrodes in Chandigarh:

- Extensive Range: LH offers a wide variety of electrode sizes to meet the specific needs of different applications, ensuring you always have the right solution.

- Reliable Performance: Known for their high quality, LH’s electrodes consistently deliver durable and effective results, even in the toughest environments.

- Local Availability: With a convenient location in Chandigarh, LH ensures easy and quick access to premium welding solutions, minimizing downtime for your operations.

- Expert Support: LH provides expert guidance to help you select the right electrodes for your specific needs, as well as support in following proper welding procedures to ensure the best results.

Conclusion

If you’re in Chandigarh and searching for a trusted supplier of abrasion-resistant electrodes, LH should be your go-to choice. With exceptional hardness, glossy deposits, and superior wear resistance, these electrodes are perfect for various industrial applications. Whether you’re working on digger teeth, bucket edges, or conveyor screws, LH’s electrodes ensure unparalleled durability and performance. Visit LH today to explore their range of top-quality welding solutions and elevate your welding operations with reliable, long-lasting products.

Reviews

There are no reviews yet.