Description

Alloy Electrode for Cast Iron Welding: A Superior Solution for Cold Welding and Repair

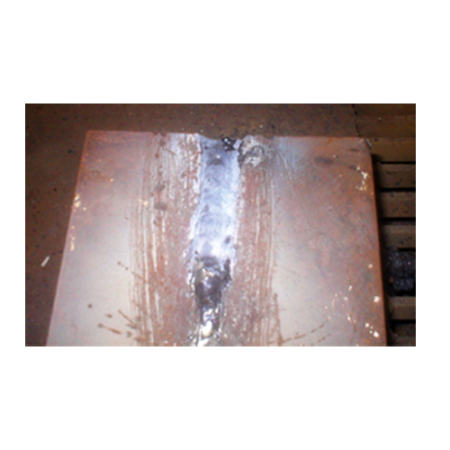

When welding cast iron, selecting the right electrode is essential for achieving a smooth, stable arc, reducing heat-affected zones, and ensuring durability. The Alloy Electrode is an excellent choice for both cold welding cast iron and joining it to mild steel. Its unique properties make it ideal for a variety of applications, including intricate repairs and surfacing cast iron parts. LH Distributor & Supplier in Chandigarh & Haryana

Properties of the Alloy Electrode

- Smooth, Stable Arc: Known for its smooth, stable arc, this electrode makes welding more predictable and controlled.

- Positional Welding: Ideal for welding in positions that are difficult to reach, ensuring flexibility in various applications.

- Minimal Base Material Mixing: The electrode reduces mixing with the base material, helping to prevent distortion and keep the heat-affected zone machinable.

- No Undercut: It avoids undercut, a common welding issue that can compromise joint integrity.

Technical Data

- Ultimate Tensile Strength (UTS): 32-38 kgf/mm², making it robust enough for demanding, heavy-duty applications.

Typical Applications

The Alloy Electrode is highly versatile and can be used in the following:

- Cold Welding of Cast Iron: No preheating is required, saving time and energy during repairs.

- Joining Cast Iron to Mild Steel: It bonds cast iron to mild steel, creating strong, lasting joints.

- Surfacing Cast Iron Parts: Ideal for surfacing parts exposed to erosion, corrosion, or high temperatures.

- Intricate Cast Iron Repairs: Perfect for repairing delicate parts like water pump housings, electric motor bodies, machine frames, and gears.

- Salvaging Castings and Machinery: Suitable for salvaging foundry castings, gearboxes, differential housings, lathe beds, sugar mill rollers, glass molds, and cast iron dies.

Using the Alloy Electrode

- Surface Preparation: Clean the welding area and check for cracks or defects that could affect the quality of the weld.

- Welding Technique: Use a short arc and low current to deposit a stringer bead, not exceeding 50mm in length. This helps control heat input and improves weld quality.

- Peening: After welding, peen the deposit to reduce residual stresses, ensuring a durable, strong joint.

Welding Current Specifications

- Current Type: AC / DC (–)

- Electrode Sizes:

- 2.5mm x 350mm

- 3.2mm x 350mm

- 4.0mm x 350mm

- Recommended Current:

- 2.5mm: 40-75 Amps

- 3.2mm: 70-110 Amps

- 4.0mm: 90-140 Amps

These specifications make the electrode suitable for a wide range of welding conditions.

LH Distributor & Supplier in Chandigarh & Haryana

For those in Chandigarh or Haryana, LH Distributor & Supplier is your trusted source for high-quality Alloy Electrodes. They offer a wide selection of welding consumables and accessories, ensuring that you have the right products for your welding needs. Whether you need to repair cast iron, join different metals, or surface components, the Alloy Electrode provides reliable, high-performance results.

Conclusion

For efficient, effective cast iron welding, the Alloy Electrode is an unparalleled solution. With its stable arc, low heat input, and minimal heat-affected zones, it is perfect for both cold welding and intricate repairs. Whether you’re handling heavy machinery repairs or salvaging foundry castings, this electrode ensures strong, durable welds. For premium welding materials and expert support, LH Distributor & Supplier in Chandigarh and Haryana is here to assist you.

Reviews

There are no reviews yet.