Description

LH Dealer & Distributor in Jammu & Kashmir

Alloy Basis

The alloy used in this electrode consists of Ni, Cr, Mn, Fe, Nb, offering superior properties for welding applications, especially in industries requiring resistance to high temperatures and corrosion.

Properties

This electrode is designed to deliver a soft, stable arc, even at low currents. The deposits produced are cold tough, with excellent resistance to scaling at high temperatures and corrosion at both normal and elevated temperatures. It also exhibits impressive thermal shock resistance, making it ideal for high-performance welding applications.

Technical Data

- UTS (Ultimate Tensile Strength): 55-60 kgf/mm²

- Elongation (L = 5d): 30-35%

Typical Applications

The electrode is highly versatile and can be used for all-position welding of various metals, including:

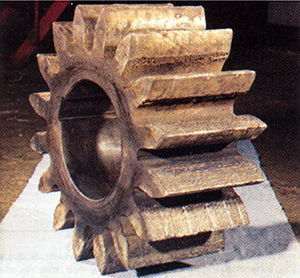

- Nickel, Inconel, Monel, and Nickel-Chromium-Iron Alloys: Perfect for welding these high-performance alloys, providing strong and durable joints.

- ENiCrFe3, HK Alloys, Steel, Stainless Steel, and Heat-Resisting Steels: Ideal for welding and joining a wide range of metal types.

- Dissimilar Metal Welding: This electrode excels in welding carbon steels, stainless steels, nickel alloys, and other dissimilar metals to one another.

- Corrosion-Resistant Fabrication: Perfect for use on equipment made of pure nickel, including corrosion-resistant tanks, containers, heat exchangers, furnace components, boilers, and fittings.

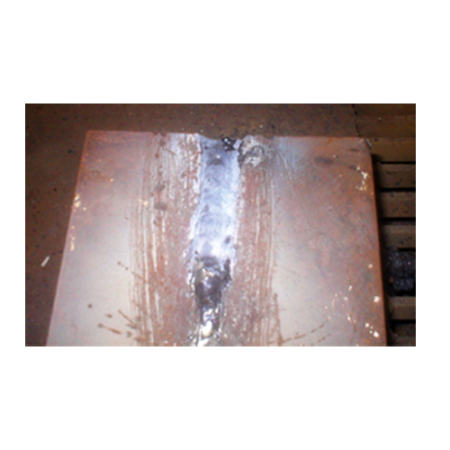

Procedure

For optimal welding results, clean the workpiece thoroughly to ensure a crack- and porosity-free deposit. Use a short arc with minimal heat input by maintaining the lowest possible amperage. A stringer bead technique is recommended, though slight weaving (2-3 times the core wire diameter) may be used. Before welding, dry the electrode for 1 hour at 300°C to remove any moisture. To prevent crater cracks, ensure that the craters are properly filled.

Welding Current

The electrode is designed for DC (+) power sources. It is available in the following sizes and current ranges:

- Size (∅ mm) / Length: 2.5×350, 3.2×350, 4.0×350, 5.0×350

- Current Range (amps):

- 2.5×350: 40-60 amps

- 3.2×350: 60-80 amps

- 4.0×350: 100-140 amps

- 5.0×350: 150-190 amps

Why Choose Us as Your LH Dealer & Distributor in Jammu & Kashmir?

As a trusted LH Dealer & Distributor in Jammu & Kashmir, we offer high-quality electrodes designed to meet the demanding needs of various industries. Whether you are working with nickel alloys, stainless steel, or heat-resistant materials, our electrodes ensure strong, durable welds and excellent resistance to high temperatures and corrosion. With reliable delivery and expert advice, we support your projects with the best welding solutions.

Contact us today for all your welding electrode needs!

Reviews

There are no reviews yet.